In the world of apparel customization, few techniques rival the versatility, durability, and vibrancy of screen printing. From custom t-shirts to hoodies, hats to jerseys, screen printing offers an unparalleled way to showcase creativity and brand identity. In this comprehensive guide, we’ll delve deep into the art and science of screen printing for apparel, exploring its history, techniques, benefits, and innovative applications.

Methods of Screen Printing

- The classic method involves creating a stencil (or screen) using a mesh screen stretched over a frame.

- Ink is then forced through the stencil onto the substrate using a squeegee, creating the desired design.

- Ideal for large-scale production runs and achieving vibrant, long-lasting prints on various surfaces.

Water-Based Screen Printing:

- Utilizes water-based inks that are eco-friendly and offer a softer feel on textiles.

- Suitable for lighter fabrics and designs requiring a more subtle, vintage look.

Discharge Screen Printing:

- Involves using discharge inks that remove the dye from the fabric, leaving behind a soft, bleached effect.

- Ideal for achieving muted, vintage-inspired designs on dark-colored garments.

The Screen Printing Process

Screen printing for apparel involves a meticulous process that requires precision, skill, and attention to detail. Here’s an overview of the typical steps involved:

Design Preparation:

- The process begins with creating or digitizing the design to be printed onto the apparel. Designs can be hand-drawn or created digitally using graphic design software.

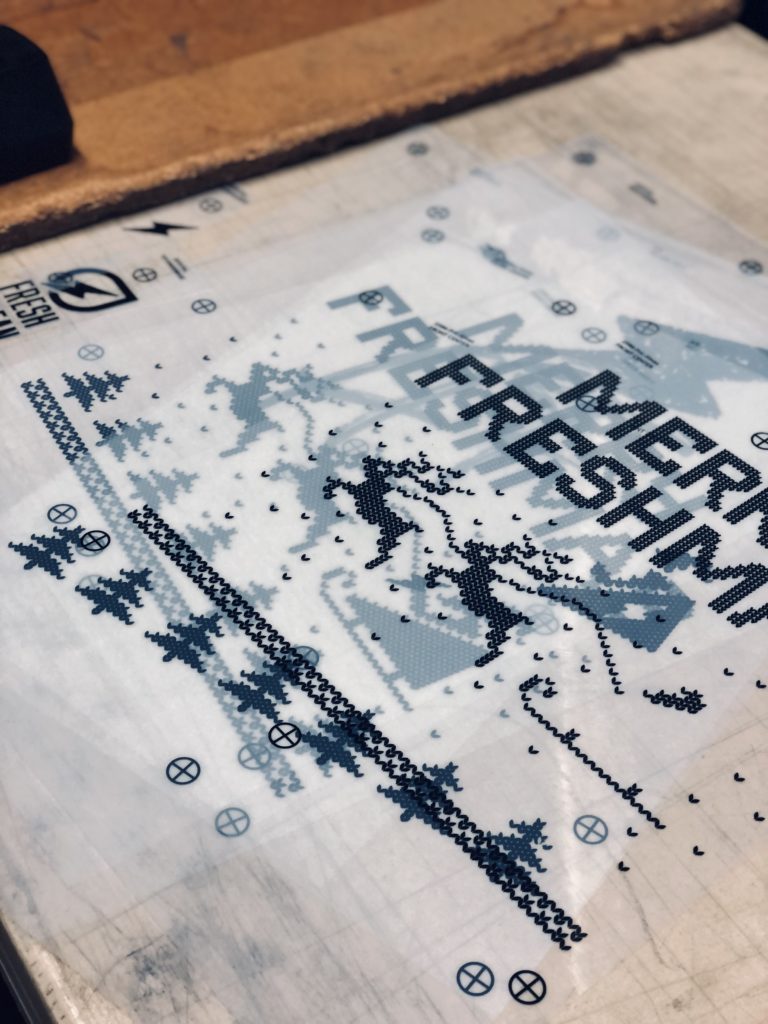

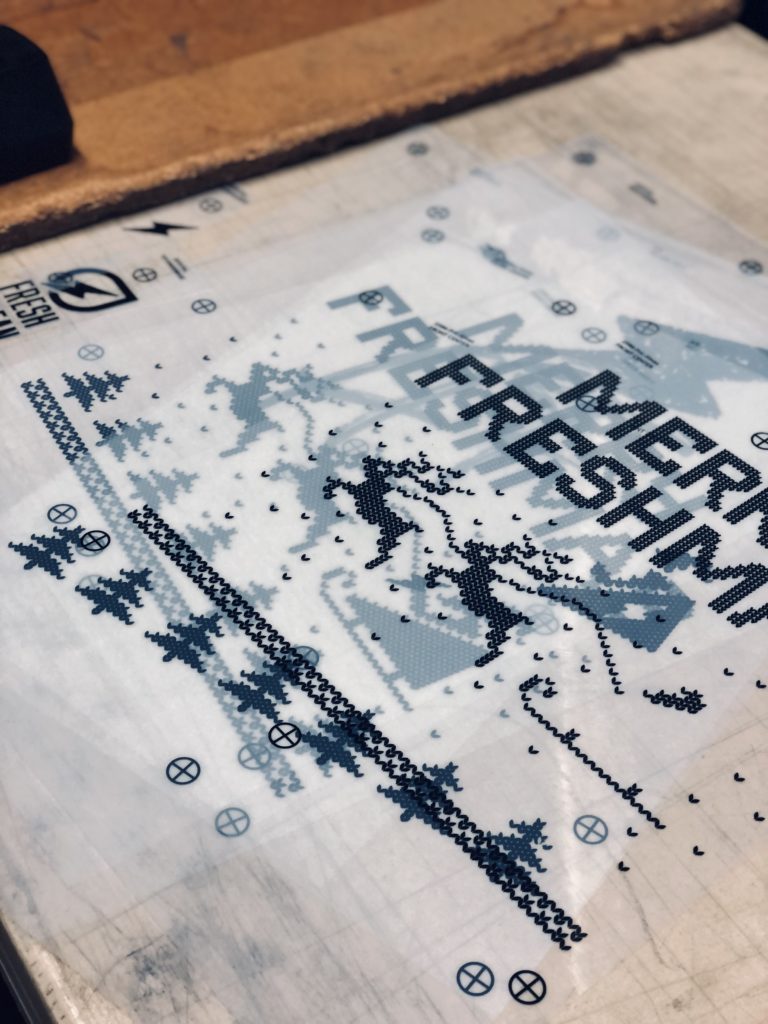

Screen Preparation:

- A mesh screen, typically made of polyester or nylon, is stretched tightly over a frame. The screen is then coated with a light-sensitive emulsion, which is exposed to UV light through a film positive of the design.

Printing Setup:

- Once the emulsion is cured, the screen is ready for printing. The apparel is placed on a flat surface, and the screen is positioned over the desired location.

Ink Application:

- Ink is applied to the screen, and a squeegee is used to push the ink through the mesh onto the apparel. Multiple passes may be required to achieve the desired color intensity and coverage.

Curing:

- After printing, the apparel is passed through a conveyor dryer or heat press to cure the ink. Curing ensures that the ink bonds with the fabric and achieves optimal durability and washability.

Benefits of Screen Printing for Apparel

Vibrant Colors

Screen printing allows for precise color matching and vibrant color reproduction, ensuring that designs pop and stand out on apparel.

Durability:

Screen printed designs are highly durable and long-lasting, withstanding repeated washings and everyday wear without fading or cracking.

Versatility:

Screen printing can be applied to a wide range of apparel materials, including cotton, polyester, blends, and even specialty fabrics like performance wear.

Cost-Effectiveness:

For large production runs, screen printing offers excellent cost-effectiveness, with lower per-unit costs compared to other printing methods.

Customization:

Screen printing allows for intricate and customizable designs, making it ideal for personalizing apparel with logos, artwork, and text.

Screen Printing offers endless possibilities for creative expression and brand promotion, whether you’re a seasoned artist, designer, or business owner. Before beginning your project, reach out to your local Screen Printer or us for guidance on the best options for the best results.

Sabio Printing

2511 W La Palma Ave. Unit T

Anaheim, CA 92801

562-888-2706